The biggest differences among these models are the automation, warranty time, and Auto Zero-Z technology.

Compresstomes® with Auto Zero-Z technology have Z-axis vibration of less than 1 micron, as confirmed by a precision laser measuring system with 0.25 micron resolution. This low Z-axis vibration is possible due to the use of precision manufactured components, 100% inspection, and careful assembly methods. Unlike other slicers there are no adjustments to slip, and no Z-axis calibration necessary by the user. The Compresstome models VF-210-0Z, VF-510-0Z, and VF-800-0Z have this Auto Zero-Z technology.

The Compresstome® VF-300 and VF-510-0Z models are fully automated models, which means that there are both ‘Single’ and ‘Continuous’ cutting modes when operating them. The micrometer sits in the control box and automatically advances your sample forward to be cut, depending on the slice thickness display that the user sets on the control box. These units can cut either one slice at a time or continuous slices and the mode is easily set via a switch on the control box. For these reasons, the VF-300 and VF-510-0Z models are excellent options for producing super thin sections, down to ~10 µm however the VF-300 only has a 1-year warranty whereas the VF-510-0Z has an industry leading 5-year warranty.

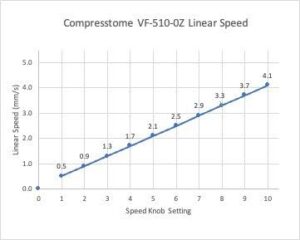

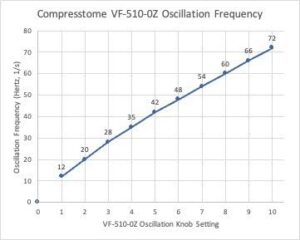

The VF-510-0Z has a sliding control box for easier access to removing and inserting the specimen tube. This means the buffer tray and the blade holder stays in place while you load the specimen. Additionally, the VF-510-0Z also has an oscillating motor cover to protect those oscillating parts from any aerosolized buffer solution coming in contact with it. This assists in the longevity of those moving parts. Because the control box is smaller in the VF-510-0Z, there is no display for the slice count or the total µm distance.

On the other hand, the VF-210-0Z is a semi-automated model meaning it can only cut one slice at a time. There is no continuous cutting mode as this model’s micrometer is a manual dial that the user needs to turn to their desired slice thickness in between each slice that is produced. Because of this manual micrometer, this model is recommended for fresh tissue slicing or producing sections >20 µm. The VF-210-0Z also has a 5-year warranty.

The VF-800-0Z is a vibrating microtome that is designed for sectioning the tissue of larger samples. It is also the only vibratome that can section large organs without freezing. With a diameter of up to 100mm, it allows the brain sectioning of cats, dogs, pigs, and monkeys. Many neuroanatomy and neuropathology experiments require sectioning entire brains from these animals. The VF-800-0Z is capable of sectioning slices for these large primates down to 40 microns. It produces even and consistent slices and it’s 5X faster than other vibratomes on the market. It also has our patented compression technology and agarose embedding process that eliminates chattermarks. The patented Auto Zero-Z technology reduces Z-axis deflection to <4 μm. The VF-800-0Z has a 1-year warranty.