Types of Microtome Blades

- Original post date:

Share on social

Microtome blades are used in microtomes to cut thin slices, or sections, of tissue samples for microscopic examination. The slices are typically less than 50 micrometers thick and are used for a variety of purposes, including histological analysis, tissue culture, and electron microscopy.

The use of cutting blades allows for precise control over the thickness and orientation of the tissue sections, ensuring that the samples are consistent and representative of the tissue as a whole. This is important for accurate and reliable results in scientific research and diagnostic testing.

General Cutting Blade Types for Microtomes

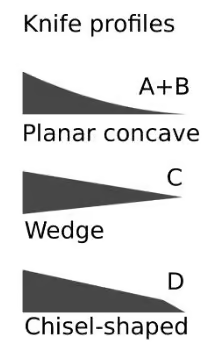

There are several types of microtome blades that are used to section samples for microscopy. Some common types include (Figure 1):

Straight blades: These blades have a straight edge and are used for making thin, uniform sections of soft tissues, such as brain tissue specimens.

Curved blades: These blades have a curved edge and are used for making thicker sections of hard tissues, such as bone or teeth.

Serrated blades: These blades have a saw-toothed edge and are used for cutting through tough or fibrous tissues, such as cartilage, muscle, and dermis.

Diamond blades: These blades are made of diamond and are used for cutting through very hard tissues, such as bone or teeth.

Cryostat blades: These blades are designed for use with a cryostat, a specialized instrument used for cutting frozen tissue samples.

Beveled blades: These blades have an angled edge and are used for making angled cuts through tissues.

In general, the type of blade used will depend on the specific properties of the tissue being sectioned and the desired thickness of the sections.

Ceramic Cutting Blades

Ceramic blades are cutting tools made from advanced ceramic materials, such as zirconia or alumina. They are known for their high hardness and wear resistance, as well as their ability to maintain a sharp edge for a long period of time. These properties make ceramic blades suitable for a wide range of cutting applications, including machining, slicing, and dicing.

One of the main advantages of ceramic blades is their ability to cut through hard and abrasive materials with minimal wear and tear on the blade. They are also resistant to corrosion and can withstand high temperatures, making them suitable for use in harsh environments. Additionally, ceramic blades are often lightweight and have a lower thermal expansion coefficient than steel blades, which can improve cutting precision.

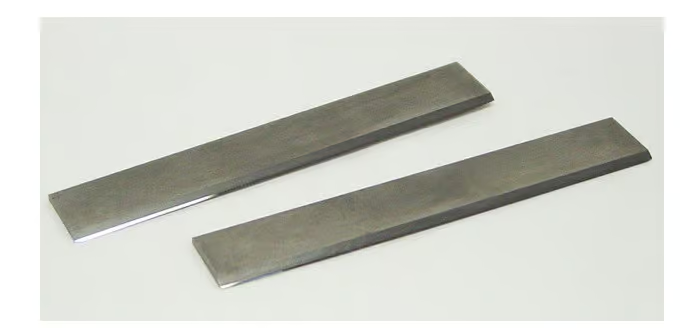

Ceramic blades are commonly used in microtomes (Figure 2) for sectioning tissue samples for microscopy. They are also used in other cutting applications, including food processing, woodworking, and metalworking. However, they are generally more expensive than steel blades and may be more prone to breaking under rough conditions.

Tungsten Carbide Cutting Blades

Tungsten carbide blades are cutting tools that are made from a composite material that consists of tungsten and carbon atoms, which are bonded together to form a crystalline structure that is extremely hard,durable, and wear-resistant. Tungsten carbide blades are used in a wide range of cutting applications, including machining, slicing, dicing, and grinding.

These blades are known for their ability to cut through hard and abrasive materials with minimal wear and tear on the blade. They are also resistant to corrosion and have a high melting point, making them suitable for use in harsh environments and high temperatures. Tungsten carbide has good thermal conductivity, which helps to dissipate heat and prevent blade overheating during cutting.

Tungsten carbide blades are commonly used in the manufacturing, construction, and scientific research industries (Figure 3). They are generally more expensive than steel blades, but their long lifespan and ability to cut through tough materials make them a cost-effective choice for many applications.

Final Thoughts

There are several types of microtome blades available, each designed for use with specific types of tissues and for producing sections of specific thicknesses. The choice of blade will depend on the properties of the tissue being cut and the desired thickness of the sections. At Precisionary Instruments, we recommend stainless steel cutting blades for soft tissue specimens like brain samples. We suggest that ceramic and tungsten carbide blades are best for more fibrous tissue specimens, or tissue samples with more vasculature–this includes cutting sections of tumors. If you have any questions about which cutting blades would be best suited for your experiments, please don’t hesitate to reach out to us!

Share on social